Improving Efficiency at Arclin

The Arclin team takes a continuous improvement approach and evaluates opportunities on a rolling basis to improve the environmental footprint of its products and plants.

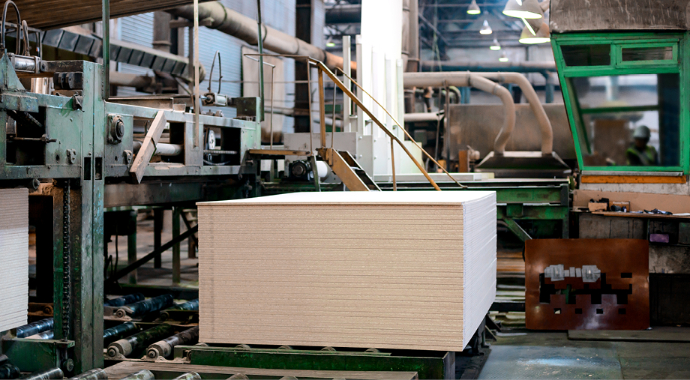

Arclin understands that chemical manufacturing processes can be resource-intensive and works to reduce its environmental impact wherever possible through efficiency and innovation. The Arclin team takes a continuous improvement approach and evaluates opportunities on a rolling basis to improve the environmental footprint of its products and plants. Over the last year, the team executed a number of projects focusing on resource efficiency.

In 2022, Arclin identified an opportunity to add new insulation to the regenerative thermal oxidizers (“RTOs”) in their plant. RTO machines use high heat to destroy volatile organic compounds created during the manufacturing process and reduce emissions of these chemicals into the environment. By insulating the RTO piping system, Arclin’s decreased natural gas consumption will avoid an estimated 430 MTCO2e annually. In a separate initiative, Arclin installed approximately 800 new LED lighting fixtures across two facilities, with energy savings equivalent to 163 MTCO2e. In total, the avoided emissions resulting from these two projects alone are equivalent to taking nearly 130 passenger vehicles off the road every year.

Beyond energy efficiency in its facilities, Arclin also looks for ways to eliminate waste. Focusing on one of its highest volume waste streams, they identified an end-user that was able to utilize wastewater byproduct rather than sending it to landfill. To further the effort, Arclin’s R&D team reformulated the recipe for a particular product, eliminating steps that created significant water waste streams. This innovative idea resulted in a reduction in total waste by 15%. The overall impact in wastewater-to-landfill was a 25% improvement in 2022 vs 2021.

It should not be assumed that the investment above was or will be profitable. Please see “LEGAL” page for important information regarding this content.